Researchers at Chalmers University of Technology in Sweden have made significant strides in developing a structural battery that could drastically reduce the weight and energy consumption of vehicles and electronic devices.

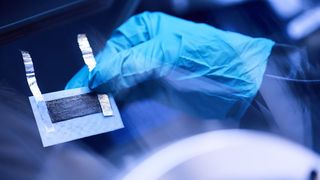

The structural battery, made from a carbon fiber composite, functions as both a power source and a load-bearing component, making it ideal for a range of purposes. “We have succeeded in creating a battery made of carbon fiber composite that is as stiff as aluminum and energy-dense enough to be used commercially. Just like a human skeleton, the battery has several functions at the same time,” said Richa Chaudhary, lead author of a paper recently published in Advanced Materials.

The battery offers an energy density of 30 watt-hours per kilogram (Wh/kg), which is lower than standard lithium-ion batteries but allows for a significant reduction in overall weight.

A huge boost for electric cars

Professor Leif Asp, who leads the research, explained that electric cars using this battery could see a huge boost in driving range. “Investing in light and energy-efficient vehicles is a matter of course if we are to economize on energy and think about future generations,” said Asp. “We have made calculations on electric cars that show they could drive for up to 70 percent longer than today if they had competitive structural batteries.”

The structural battery also has improved stiffness, now reaching 70 gigapascals (GPa), allowing it to carry loads as effectively as aluminum while being much lighter. Asp stated, “In terms of multifunctional properties, the new battery is twice as good as its predecessor – and actually the best ever made in the world.”

Although the technology is still under development, Sinonus AB, a spin-off from Chalmers Ventures, is working to bring this innovation to the market. Asp envisions that lightweight laptops, mobile phones, and electric vehicle components will be among the first products to benefit from the structural battery.

More from TechRadar Pro

Services Marketplace – Listings, Bookings & Reviews