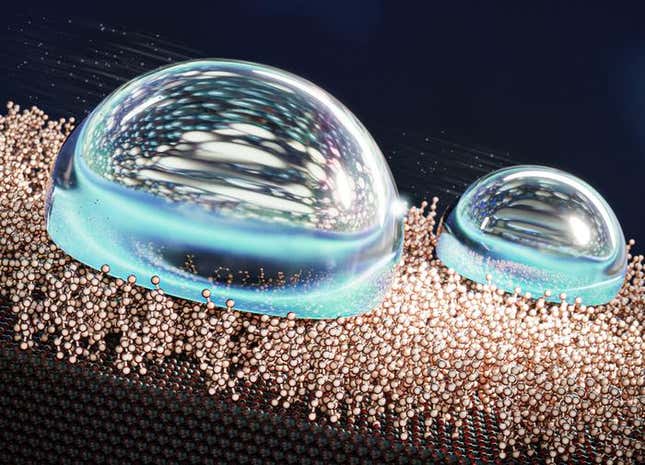

A duck’s back is not the only slippery surface water is prone to slide off of. Researchers have developed a new method of coating surfaces in a liquid-like layer to make them extra slick.

The Finland-based research team, led by Sakari Lepikko of Aalto University, developed a reactor to create the surfaces, which are referred to as self-assembled monolayers, or SAM. These monolayers feature a fluid-like surface resulting from layers of molecules that are covalently bound to a piece of silicon material, much in the same way that liquid molecules are held together.

Advertisement

This dramatically reduces the surface’s friction, allowing droplets of water to glide across with ease. The researchers are referring to this manufacturing process as a first of its kind. The paper documenting their research was published today in Nature Chemistry.

Advertisement

Advertisement

“Our work is the first time that anyone has gone directly to the nanometer-level to create molecularly heterogenous surfaces,” Lepikko said in a press release. “The main issue with a SAM coating is that it’s very thin, and so it disperses easily after physical contact. But studying them gives us fundamental scientific knowledge which we can use to create durable practical applications.”

Lepikko and his colleagues created the SAMs using a vapor deposition reactor—a machine that deposits thin layers of materials onto surfaces through the condensation of vaporized material. In this case, the process involved spraying the silicon surface with a chemical known as octyltrichlorosilane to create the liquid-like surface. By varying the amount of time the silicon material was in the reactor, the researchers could make the SAM more or less slippery.

Advertisement

During testing of these surfaces, the team found that both short growth times (approximately 30 seconds) and longer growth times (upwards of four hours) produced the slickest surfaces when compared to intermediate growth times. Shorter growth times caused water droplets on the surface to spread out while longer growth times cause droplets to bead up more dramatically.

“The results showed more slipperiness when SAM coverage was low or high, which are also the situations when the surface is most homogeneous,” Lepikko said in the release. “It was counterintuitive that even low coverage yielded exceptional slipperiness.”

Advertisement

Studying ways to make surfaces more slippery may sound like a hilariously nefarious pursuit, but this research has many common applications. In 2016, a research team from Pennsylvania State University created a 2.5-micron thick coating inspired by the waxy coating on plants, which allows thick fluids like ketchup and mustard to slide right off of a surface. Lepikko notes that his team’s research also has practical properties like de-icing and anti-fogging as potential applications for the SAMs his team worked on, as well as creating self-cleaning surfaces.

More: The World’s Blackest Ink Will Make Your Doodles Look Like Empty Voids on the Page

Services Marketplace – Listings, Bookings & Reviews